About the project

The REEsilience project is funded by the European Union’s research and innovation programme Horizon Europe and coordinated by the Institute for Precious Metals and Technology (STI) of Pforzheim University, Germany and will last until June 2026. The consortium comprises 16 project partners and two associated partners from ten European countries (Austria, Belgium, France, Germany, Netherlands, Poland, Slovenia, Spain, Sweden and the United Kingdom).

Challenges & solutions

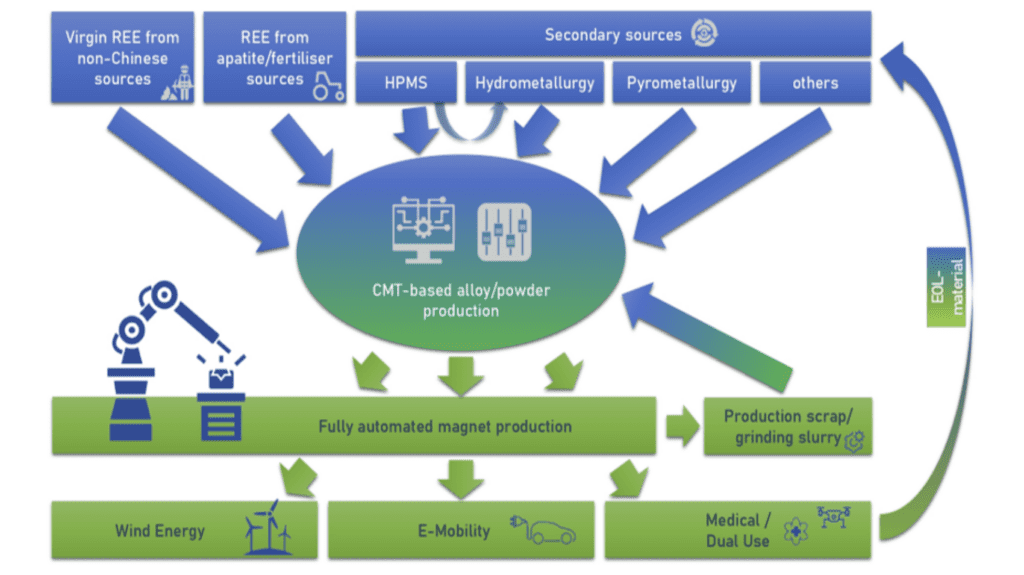

Rare-earth elements (REEs) are necessary materials to achieve the green and digital transition in Europe. They are an essential part of permanent magnets, strong and very efficient magnets used in, for example, electric vehicles, wind turbines and sensor applications. The market for REE-based magnets itself is relatively small – approximately €6.5 billion per year – however, its downstream leverage is enormous: the mobility business in the EU alone is expected to grow to about €500 billion by 2030, with 6 million jobs. While being a world leader in, for example, the manufacturing of electric motors, the EU is fully import-dependent along the entire value chain of REE-magnet materials. Despite a growing market, European magnet production capacity is under-utilised and tends to serve specialised niche applications. In addition, REE magnets are increasingly imported as part of motor and generator assemblies and products.

The objectives of REEsilience

Partners:

Subscribe

Subscribe

Members

Members